Lead

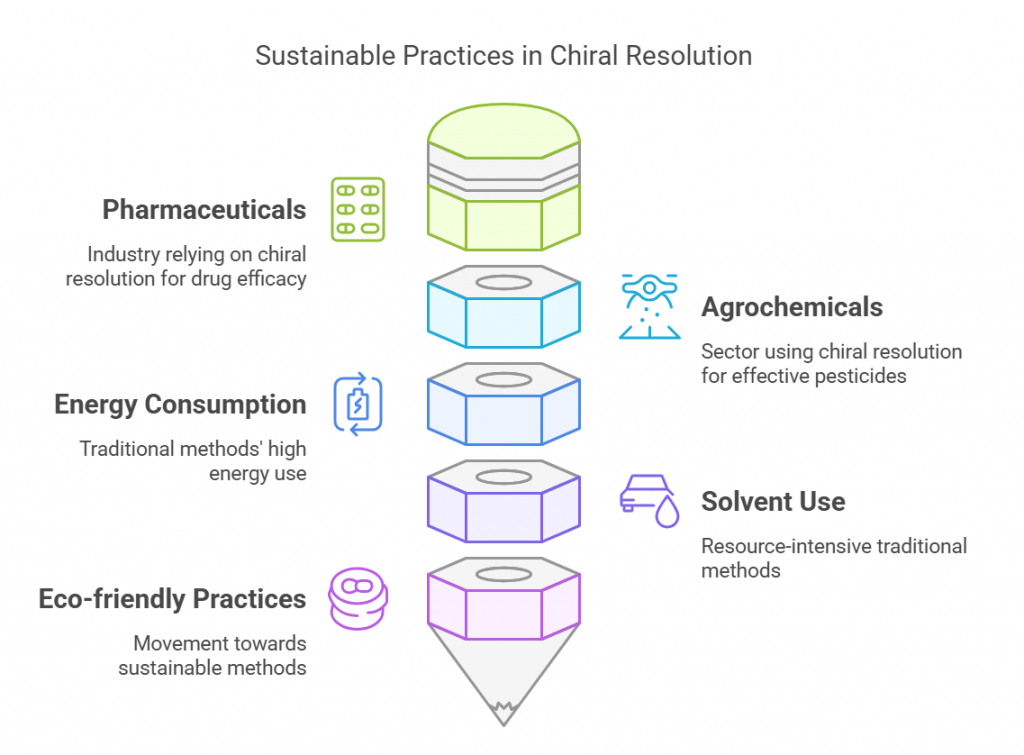

Sustainability is becoming an increasingly important consideration across many industries, and chiral resolution is no exception. The separation of enantiomers, essential in pharmaceuticals, agrochemicals, and other sectors, has traditionally relied on methods that consume large amounts of energy, solvents, and other resources. As industries become more aware of the environmental impact of these processes, there is a growing movement toward more sustainable and eco-friendly practices in chiral resolution.

1. Why Sustainability is a Growing Concern in Chiral Resolution

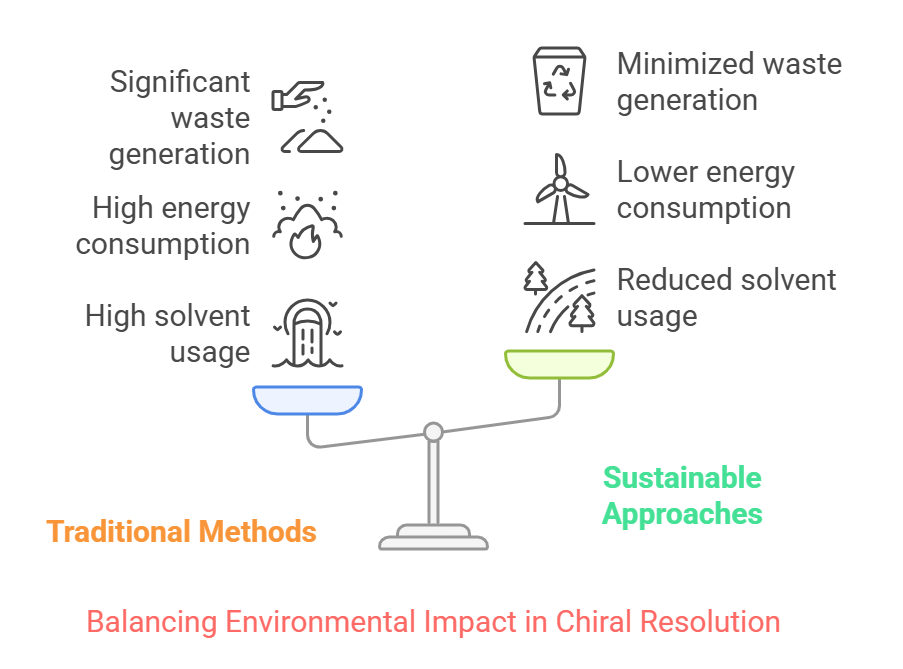

The environmental impact of chemical manufacturing has been a major concern for decades, and chiral resolution processes are no exception. Traditional methods, such as high-performance liquid chromatography (HPLC) and crystallization, often require large amounts of solvents, energy, and other materials, which can contribute significantly to the industry’s carbon footprint. In addition, the waste generated from these processes, particularly solvents, poses a significant disposal problem, potentially leading to environmental contamination if not properly managed.

As global industries face increasing pressure to reduce their environmental impact, driven by both regulatory bodies and public demand, sustainability is becoming a key concern in the development of new chiral resolution techniques. Companies are looking for ways to reduce waste, minimize solvent use, and lower energy consumption while maintaining high levels of efficiency and enantiomeric purity in their processes. These challenges are being met through innovations that align with the principles of green chemistry, which emphasizes the reduction of harmful substances and the development of energy-efficient processes.

2. Overview of Green Chemistry Principles

Green chemistry, sometimes referred to as sustainable chemistry, focuses on designing chemical processes and products in a way that reduces or eliminates the use and generation of hazardous substances. The 12 principles of green chemistry, introduced by Paul Anastas and John Warner in the 1990s, provide a framework for creating more sustainable chemical processes. These principles include designing safer chemicals, using renewable feedstocks, minimizing waste, improving energy efficiency, and reducing the environmental and human health impacts of chemical production.

In the context of chiral resolution, green chemistry principles can be applied by developing more efficient separation techniques, using less hazardous solvents, and optimizing processes to minimize waste. Supercritical fluid chromatography (SFC), for example, is an innovation in the field that uses carbon dioxide as a solvent, reducing the need for toxic organic solvents. This technique not only improves sustainability but also often leads to faster, more efficient separations.

Supercritical Fluid Chromatography (SFC)

How SFC Minimizes Solvent Usage and Reduces Environmental Impact

Supercritical fluid chromatography (SFC) is a powerful technique that has gained attention for its potential to minimize solvent use and reduce the environmental impact of chiral resolution processes. Unlike traditional liquid chromatography, which relies on large amounts of organic solvents, SFC uses carbon dioxide (CO₂) as the primary mobile phase, often in combination with a small amount of an organic modifier. CO₂, in its supercritical state, behaves like a liquid but has the diffusivity of a gas, making it an ideal solvent for chromatographic separations.

The major environmental advantage of SFC is its ability to significantly reduce the volume of organic solvents required. Traditional HPLC can consume liters of solvents, whereas SFC typically requires only milliliters. This reduction in solvent use not only lowers the cost of raw materials but also reduces the environmental burden associated with solvent disposal and recovery. Moreover, CO₂ used in SFC is often recycled from industrial processes, making it a more sustainable choice. SFC also operates at lower temperatures, reducing the energy required for separations.

Another important environmental benefit of SFC is that CO₂ is non-toxic and non-flammable, unlike many organic solvents used in traditional chromatography. This makes SFC a safer option for laboratory workers and reduces the risk of environmental contamination during production.

Industrial Applications of SFC

SFC has been increasingly adopted in various industries for its ability to efficiently separate chiral compounds with minimal environmental impact. In the pharmaceutical industry, SFC is used to separate enantiomers of drug candidates, ensuring that only the active enantiomer is present in the final product. The efficiency and scalability of SFC make it ideal for both research and development as well as large-scale production.

The food and fragrance industries have also embraced SFC as a tool for separating chiral compounds, which often play a critical role in the sensory characteristics of products. By reducing solvent usage, SFC aligns with the growing consumer demand for more sustainable and eco-friendly production practices.

In addition to its environmental benefits, SFC offers faster separation times compared to traditional liquid chromatography, making it a cost-effective solution for large-scale industrial applications. Companies can reduce both processing times and operational costs while maintaining high standards of purity and efficiency.

Case Study: SFC in Drug Development

One of the most compelling examples of SFC’s potential in chiral resolution comes from its application in drug development. In the case of ibuprofen, a common nonsteroidal anti-inflammatory drug (NSAID), SFC has been used to separate the active S-enantiomer from the inactive R-enantiomer. This separation is crucial, as the S-enantiomer is responsible for ibuprofen’s therapeutic effects, while the R-enantiomer has no significant anti-inflammatory properties.

Traditional methods of separating ibuprofen enantiomers relied on liquid chromatography, which required large amounts of organic solvents and extended processing times. By switching to SFC, manufacturers were able to significantly reduce the volume of solvents used and speed up the separation process. Not only did this result in a more sustainable production method, but it also lowered costs and improved overall efficiency.

SFC has also been successfully applied to the separation of other pharmaceutical compounds, such as ketoprofen and naproxen, both of which have chiral centers. In these cases, SFC provided a more environmentally friendly alternative to HPLC, with comparable or superior separation efficiencies. The ability to scale up SFC processes for industrial production without compromising on purity or yield makes it an attractive option for the pharmaceutical industry moving forward.

3. Recycling and Racemization of Unwanted Enantiomers

The Process of Racemization and Recycling

Racemization and recycling of unwanted enantiomers are vital components of sustainable chiral resolution. Racemization refers to the process of converting one enantiomer of a racemic mixture into the other, thus allowing for the recycling of the undesired enantiomer. This process is particularly important in large-scale production, where significant quantities of the unwanted enantiomer can accumulate, leading to waste if not properly managed.

The racemization process typically involves the use of a catalyst that can selectively convert the unwanted enantiomer back into its racemic form. This racemic mixture can then be subjected to further resolution, allowing for the recovery of both enantiomers. By integrating racemization into the production process, manufacturers can minimize waste and improve the overall efficiency of chiral resolution.

Recycling unwanted enantiomers through racemization is especially valuable in the pharmaceutical industry, where regulatory standards require high levels of purity for drug compounds. Rather than discarding the unwanted enantiomer, which would result in a significant loss of material and increased costs, racemization allows companies to recover and reuse these compounds, reducing both waste and production costs.

Applications in Large-Scale Production

Racemization and recycling have become increasingly important in large-scale production settings, particularly in industries where high enantiomeric purity is required, such as pharmaceuticals and agrochemicals. The ability to recycle unwanted enantiomers reduces the need for extensive raw material input, lowering both costs and environmental impact. In pharmaceutical manufacturing, this approach is particularly advantageous, as the cost of producing enantiopure compounds is often high due to the complexity of the separation processes involved.

One of the key benefits of racemization in large-scale production is its ability to reduce the overall waste generated during chiral resolution. By converting unwanted enantiomers back into a racemic mixture and subjecting them to further separation, companies can significantly improve the yield of their processes. This is particularly important for high-value compounds, where even small losses of material can have a significant impact on profitability.

Additionally, racemization can be integrated into continuous production processes, further enhancing efficiency. By constantly recycling unwanted enantiomers within the production line, manufacturers can maintain a steady output of enantiopure compounds without the need for additional raw materials. This approach aligns with the principles of green chemistry, promoting sustainability while also improving economic viability.

Case Study: Recycling in the Production of Pharmaceutical Intermediates

A notable example of racemization and recycling in large-scale production comes from the synthesis of the pharmaceutical intermediate naproxen, a widely used nonsteroidal anti-inflammatory drug. In the production of naproxen, the S-enantiomer is the active form, while the R-enantiomer is inactive. Rather than discarding the unwanted R-enantiomer, manufacturers implemented a racemization process to convert it back into the racemic mixture, which could then be reprocessed to recover the active S-enantiomer.

By integrating racemization into the production process, the company was able to significantly reduce waste and improve overall yield. This not only lowered production costs but also minimized the environmental impact of the manufacturing process by reducing the amount of raw materials required. The success of this approach in the production of naproxen has since led to its adoption in the synthesis of other chiral pharmaceuticals, demonstrating the broad applicability of racemization and recycling in industrial-scale chiral resolution.

4. The Role of Green Solvents and Energy Efficiency

Exploring Alternatives to Traditional Solvents

One of the key principles of green chemistry is the reduction or elimination of hazardous solvents in chemical processes. In chiral resolution, traditional solvents such as methanol, acetonitrile, and dichloromethane are commonly used, but these solvents are often toxic, flammable, and environmentally damaging. As industries move toward more sustainable practices, there is a growing interest in exploring alternatives to these traditional solvents.

Supercritical CO₂, as used in SFC, is one such alternative that offers significant environmental benefits. Other green solvents, such as ionic liquids and deep eutectic solvents, have also gained attention for their potential to reduce the environmental impact of chiral resolution processes. These solvents are non-volatile, reducing the risk of air pollution, and can often be recycled and reused within the production process, further reducing waste.

In addition to reducing toxicity, green solvents also contribute to energy efficiency. Many green solvents can operate effectively at lower temperatures and pressures compared to traditional solvents, reducing the overall energy required for chiral separations. This makes them an attractive option for industries looking to improve both the sustainability and cost-effectiveness of their production processes.

5. Energy-Efficient Techniques in Large-Scale Separations

Energy efficiency is a critical consideration in the development of sustainable chiral resolution processes. Traditional methods such as HPLC can be energy-intensive due to the high pressures and temperatures required for effective separation. In contrast, emerging techniques such as SFC and membrane-based separations offer significant improvements in energy efficiency.

SFC, in particular, operates at lower temperatures and requires less energy for solvent recovery, making it a more energy-efficient option for large-scale separations. Similarly, membrane-based techniques, which rely on selective permeability rather than chemical reactions, can operate under ambient conditions, further reducing energy consumption.

The integration of renewable energy sources, such as solar or wind power, into chiral resolution processes is also gaining attention as industries seek to reduce their carbon footprint. By powering energy-intensive processes like chromatography and racemization with renewable energy, companies can further enhance the sustainability of their operations while maintaining high levels of efficiency.

6. Future Directions and Innovations

How Green Chemistry is Shaping Future Technologies in Chiral Resolution

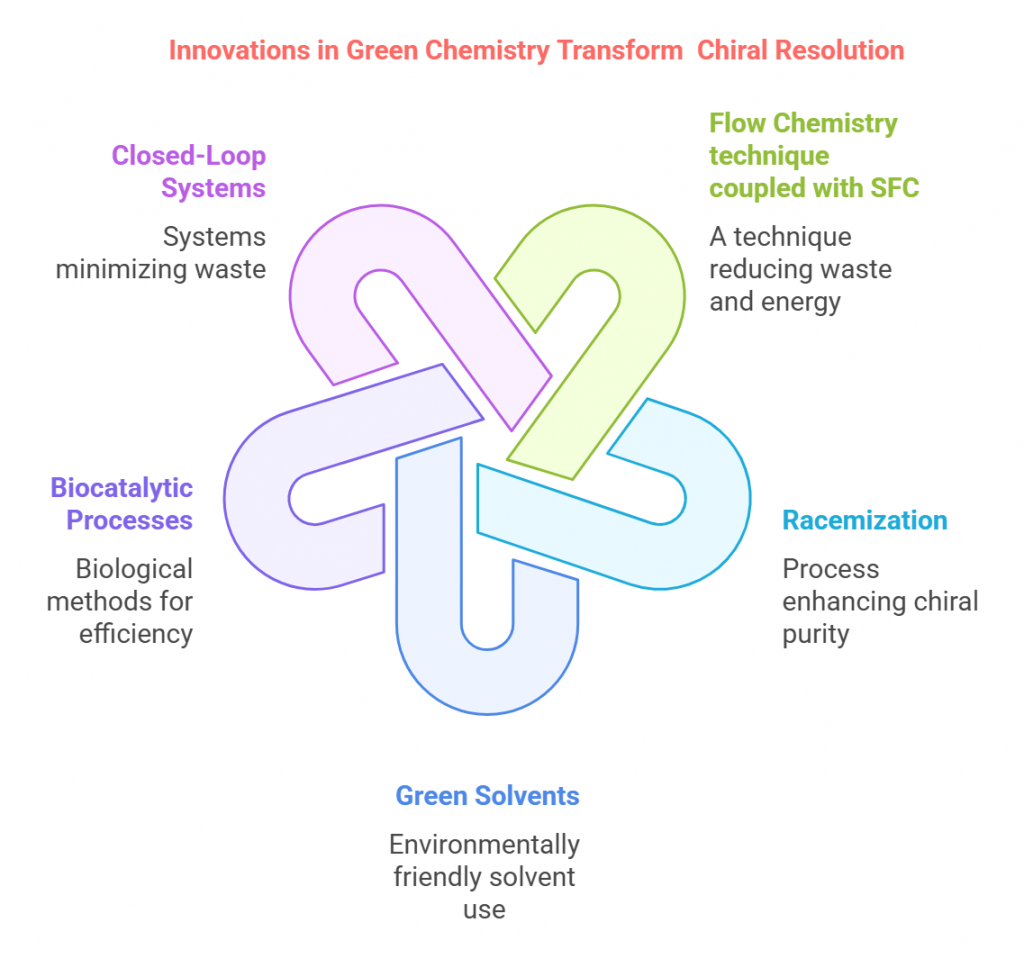

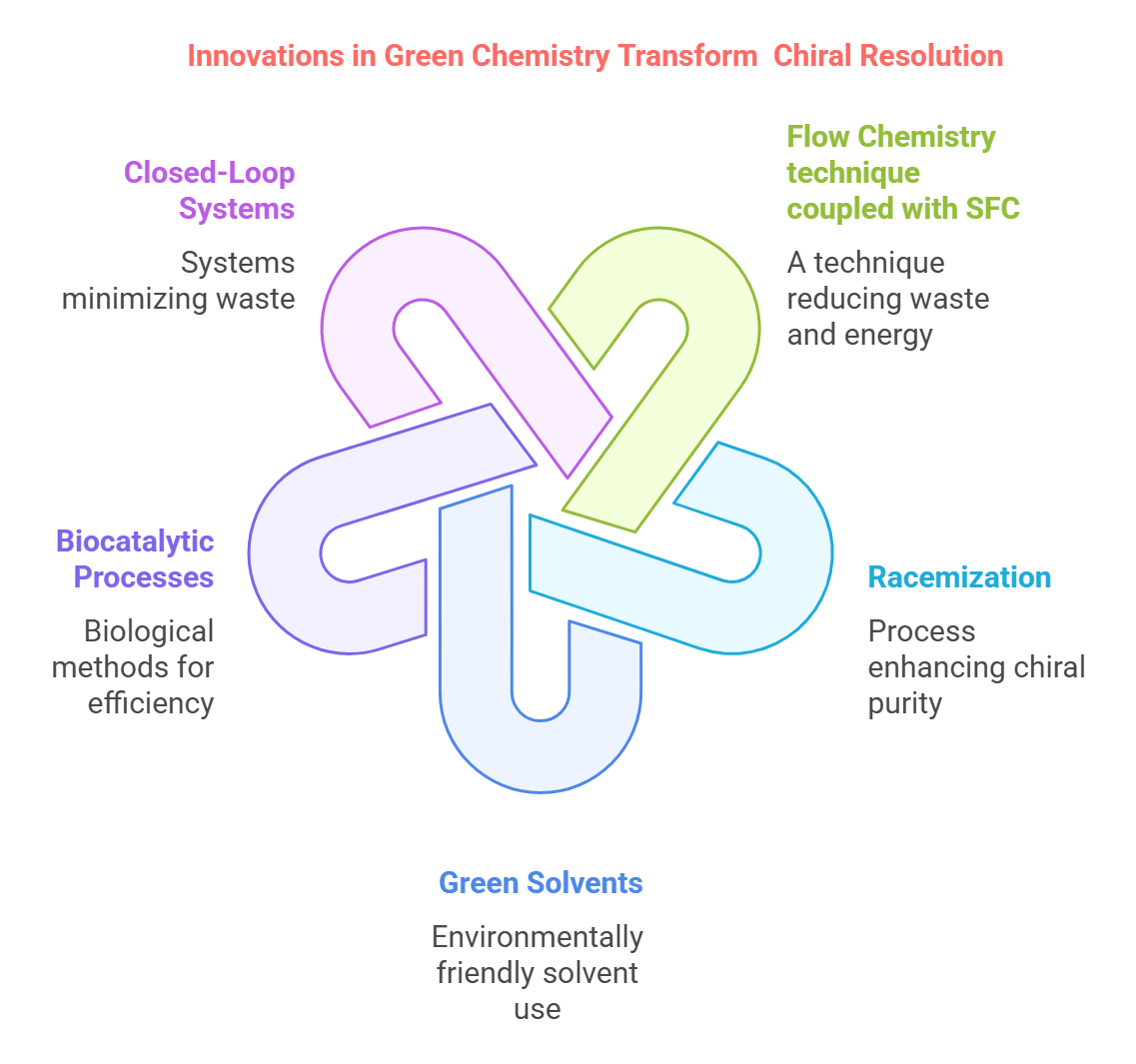

One area of innovation is the development of biocatalytic processes for chiral resolution. Enzymes, which are naturally chiral, can be used to selectively catalyze the conversion of one enantiomer in a racemic mixture, providing a highly efficient and sustainable method of separation. Biocatalytic processes often operate under mild conditions, reducing the need for energy-intensive heating or cooling, and can be carried out in aqueous solutions, minimizing the need for organic

Another promising direction is the use of flow chemistry in chiral resolution. Flow chemistry involves the continuous processing of chemicals through a series of reactors, offering greater control over reaction conditions and improving the efficiency of separations. By integrating flow chemistry with techniques such as SFC or membrane-based separations, companies can achieve higher throughput while reducing energy consumption and waste generation.

The Push Toward Zero-Waste and Closed-Loop Systems

A key goal of green chemistry is the development of zero-waste and closed-loop systems, where all materials are reused or recycled within the production process, eliminating waste entirely. In the context of chiral resolution, this means integrating recycling and racemization processes to ensure that no unwanted enantiomers are discarded. Instead, these compounds are continuously reprocessed and converted back into usable materials, minimizing both waste and the need for new raw materials. Closed-loop systems are already being implemented in some industries, particularly in the production of high-value pharmaceuticals. By combining techniques such as racemization, recycling, and energy-efficient separations, companies are able to achieve a more sustainable production process that aligns with the principles of green chemistry. As research continues to advance in this area, it is likely that we will see more widespread adoption of closed-loop systems in chiral resolution, leading to a future where chemical production is both economically viable and environmentally sustainable.

A summary of sustainable chiral resolution approaches, aligned with green chemistry principles, is presented visually for easy understanding.

As the demand for more sustainable chemical processes continues to grow, green chemistry is playing an increasingly important role in shaping the future of chiral resolution technologies. Innovations in solvent use, energy efficiency, and waste reduction are driving the development of new techniques that align with the principles of green chemistry. These advancements are not only helping to reduce the environmental impact of chiral resolution but also improving the overall efficiency and cost-effectiveness of the process.

7. Conclusion

The Path Forward for Sustainability in Chiral Resolution

As industries continue to prioritize sustainability, the future of chiral resolution will be shaped by innovations that align with the principles of green chemistry. Techniques such as supercritical fluid chromatography (SFC), racemization, and the use of green solvents are already making a significant impact, reducing waste, energy consumption, and solvent use in large-scale operations. The development of biocatalytic processes and the integration of closed-loop systems further enhance the potential for zero-waste production, paving the way for a more sustainable approach to chiral resolution.

The push toward greener practices in chemical manufacturing is not just an environmental imperative; it is also a key driver of economic efficiency. By reducing the need for raw materials, minimizing waste, and improving energy efficiency, companies can lower their production costs while maintaining high standards of quality and purity. As research continues to advance in this field, the adoption of sustainable practices in chiral resolution will become increasingly widespread, helping to ensure a more sustainable future for the chemical industry as a whole.

Further Reading

Hangh, X. (2024). Advancement of Chiral Resolution and Separations: Techniques and Applications. Highlights in Science, Engineering and Technology, 83, pp.305-310.

Malacarne, F. (2024). Unconventional Approaches for Chiral Resolution. Analytical and Bioanalytical Chemistry, 416, pp.3677-3685.

Pinto, M. (2020). Chiral Separations in Preparative Scale: A Medicinal Chemist’s Viewpoint. Journal of Medicinal Chemistry, 63(14), pp.7889-7899.

Sui, H. (2023). Strategies for Chiral Separation: From Racemate to Enantiomer. Royal Society of Chemistry.

Al-Sulaimi, S. et al., Emerging Developments in Separation Techniques and Analysis of Chiral pharmaceuticals. Molecules 2023, 28, 6175. https://doi.org/10.3390/molecules28176175

Céline Rougeot et al., Application of Continuous Preferential Crystallization to Efficiently Access Enantiopure Chemicals, Org. Process Res. Dev. 2015, 19, 12, 1809–1819. https://doi.org/10.1021/acs.oprd.5b00141

Ganjar Fadillah et al., One-stage chiral enrichment process by continuous flow electrodialysis with molecularly imprinted membrane. Separation and Purification Technology, Volume 305, 15 January 2023. https://doi.org/10.1016/j.seppur.2022.122492